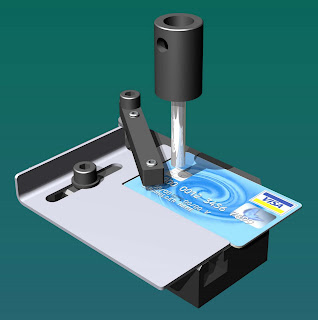

S0281 - Reinforcing Bar Rebend Test to BS4449, BS4482 & BS4483

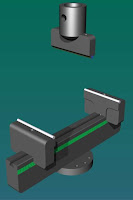

Used for testing reinforcing bars or reinforcement bar ( Rebar ) for the construction industry. The way that mass produced R ebar is made requires test for consistency throughout a products manufacture life cycle. The sample is placed on the lower support rollers, then bent to a certain angle (depending upon test). It is then treated (heated to a specific temprature) and then rebent, back to straight and an observations are taken.